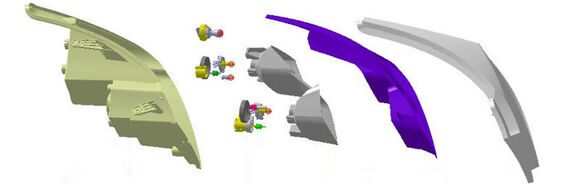

Finished goods assembly

1. Casting of products is made both on two-color, and on one-color automatic molding machines with the use of all production requirements to molding of products from plastic, such as material preparation – the drying, dispensing of color and the modes of molding excluding the deformation of a surface leading to diffraction of light and formation of shrinkage cavity and dross.

2. Aluminization of a reflector in the vacuum painting camera with the use of pure aluminum with purity 99,5 and a high-temperature varnish of the UP5403, KUV-1000 brands is made for prevention of yellowing, lack of "orange peel" surface and adhesion increase.

3. Thermal welding of a product with check of a clearance gap on a basic matrix of model.

4. Installation of systems of lighting, controlling system and fastener system.

5. The packing preventing from impact of shock strain, thermal loading and differences of humidity.