Manufacturing of mold

At the stage of mold manufacturing our engineers as soon as possible make schematic drawings and 3D model that are handed over to client approval. The process of project engineering and production of molds consists of several stages. At every stage project head manager, development engineers and engineers hold joint conferences for discussion of deal.

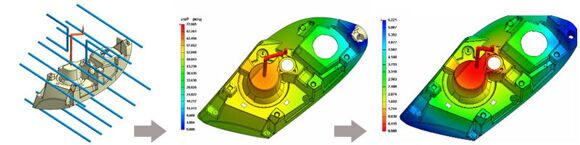

Design team prepare flow analysis of molds, with the help of special software support make end-to-end assessment of mold filling process , foresee all possible deformations, occurring of some damages and the other small special aspects of designing. At the initial phase all details of casting are controlled, such activity detailed warrants 100% success of mold acceptance.

Our company uses ERP system (Enterprise Resource Planning System) for unification of all company divisions and all necessary functions in one computer system that serves current demands of these divisions. Development of such single system - it is challenging task, but in cases of mold production the use of such system warrants consistency of production and distinct performance monitoring of each division. ERP system maintain a single database in case of all subdivisions and issues, so access to information is easier and, the main thing, subdivisions have the opportunity to share information.

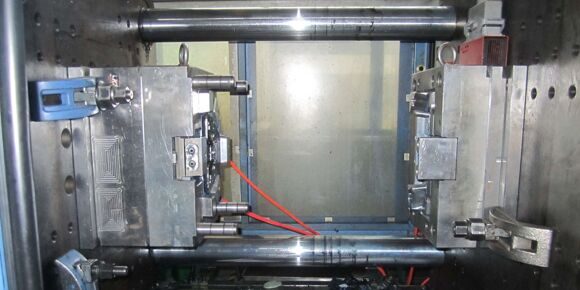

The process of mold production takes place when using the most modern equipment and advanced technologies. Our factory has equipped placements for running of full tool-making facilities. Workshops are equipped on the one hand with hand lathes, continuous polishing milling machines, on the other – with exacting machining program-controlled center module: EDM wire machine, punch machine, three-axis-controlled mill and other machines. This allows to produce molds of any complexity and to set the production of molds for manufacture of plastic materials of the highest quality and accurately duplicated a shape of future products. The material is chosen taking into account future quantity of products (there is a possibility to produce molds for production up to 1 000 000 pieces) and accuracy of casting. The order for production of a mold includes its test and creation of samples of future products from the material provided by the customer, and also the form undergoes testing on the automatic molding machine.